We will see how virtual reality welding training impacts the learner and trainer experience. Immersive technologies such as Virtual Reality, Augmented Reality or even 3D bring a real added value to the learners’ experience, but also to that of the trainers. But what are the real advantages of these immersive technologies in the learning of the welding profession?

Welding is a complex profession that has evolved over time. The evolution of health and safety standards and of working conditions in general have made it a less strenuous job than it was in the 19th and 20th centuries.

Technology has also entered the game. The numerically controlled machines are a perfect example. They enhance safety and relieve the welder who can now concentrate more on his core business.

For training, it’s the same thing!

Here are our Top 5 reasons why you should integrate VR in your welding training:

Why switch to virtual reality for vocational training in industry?

Repetition is the key and simulation facilitates practicing as much as necessary. By relieving the apprentice of the part where he has to equip himself, prepare his welding station, and put away his equipment, we let him concentrate on the most important aspect: working on and perfecting his gesture and technique.

Another important point is the visual aids. These cues will guide the learner in the acquisition of his skills. These visual guides will allow him to work on his angle of application, his speed and his precision in order to make his gesture as perfect as possible.

Moreover, these aids are dissociable! The trainer can easily decide to work on only one of these aspects at a time, and then start combining them as he goes along.

Unparalleled feedback

This information is a real gold mine for him. At a glance, he will be able to visualize the strengths and weaknesses of each learner. He will be able to identify the areas of improvement for each learner.

The trainer will now be able to see the progress of each learner, skill by skill. This is a major asset for the trainer who will be able to have an overall view of the training of his class, but also an individualized view of each one.

This information will allow him to adapt the difficulty of the exercises he proposes according to the qualities of each student.

Correcting the learners’ posture

The posture that welders adopt while practicing is a real issue. If a learner adopts poor posture when training for the trade, there is a good chance that he will keep it remain throughout his career. Poor posture can have detrimental effects on the learner’s physical health over time.

When a learner practices in a booth, he or she is often isolated from the trainer. The suits used can also prevent the trainer from appreciating the movements and posture. The trainer cannot correct the learner’s posture in real time. The risk is that the trainer will anchor this bad habit. A habit that will be difficult to get rid of in the long term.

Moreover, he will only be able to analyze the weld once it is completed.

The advantage of the simulator is that it will remove all these barriers so that the trainer can concentrate on transmitting his knowledge.

Personalize the learning process according to the level of each student

This is the basis of all learning.

For welding, the principle is the same: start easy then raise the level little by little. Your learners will start on simple parts guided by the visual aids we talked about. By dint of repetition and practice, the learner will be able to practice on more and more complex parts, and like the little wheels on a bicycle, remove the visual aids in order to become totally autonomous.

Adapt the simulation to your own tools

The advantage of simulation in training is that everything is adaptable and customizable. This is the role of the so-called simulation variables. In a few clicks, it is possible to modify the metal used, the heating temperature of the tool, the type of process used… It is the simulator that adapts to the trainer, not the other way around.

By playing with these simulation variables, you will be able to make the tool a real replicate of your reality. This is where all the potential and interest of Virtual Reality welding training lies: making it as realistic as possible.At a time when preserving and transmitting our know-how is becoming an increasingly important issue, virtual reality offers a reliable, relevant and up-to-date solution. Emancipated from the gadget image that has stuck to it since its inception, VR is becoming a serious alternative for training in manual trades.

Yet, the welding profession is no exception to the rule: welding training using virtual reality is different from traditional methods. It will complement your existing training to make it more effective and engaging.

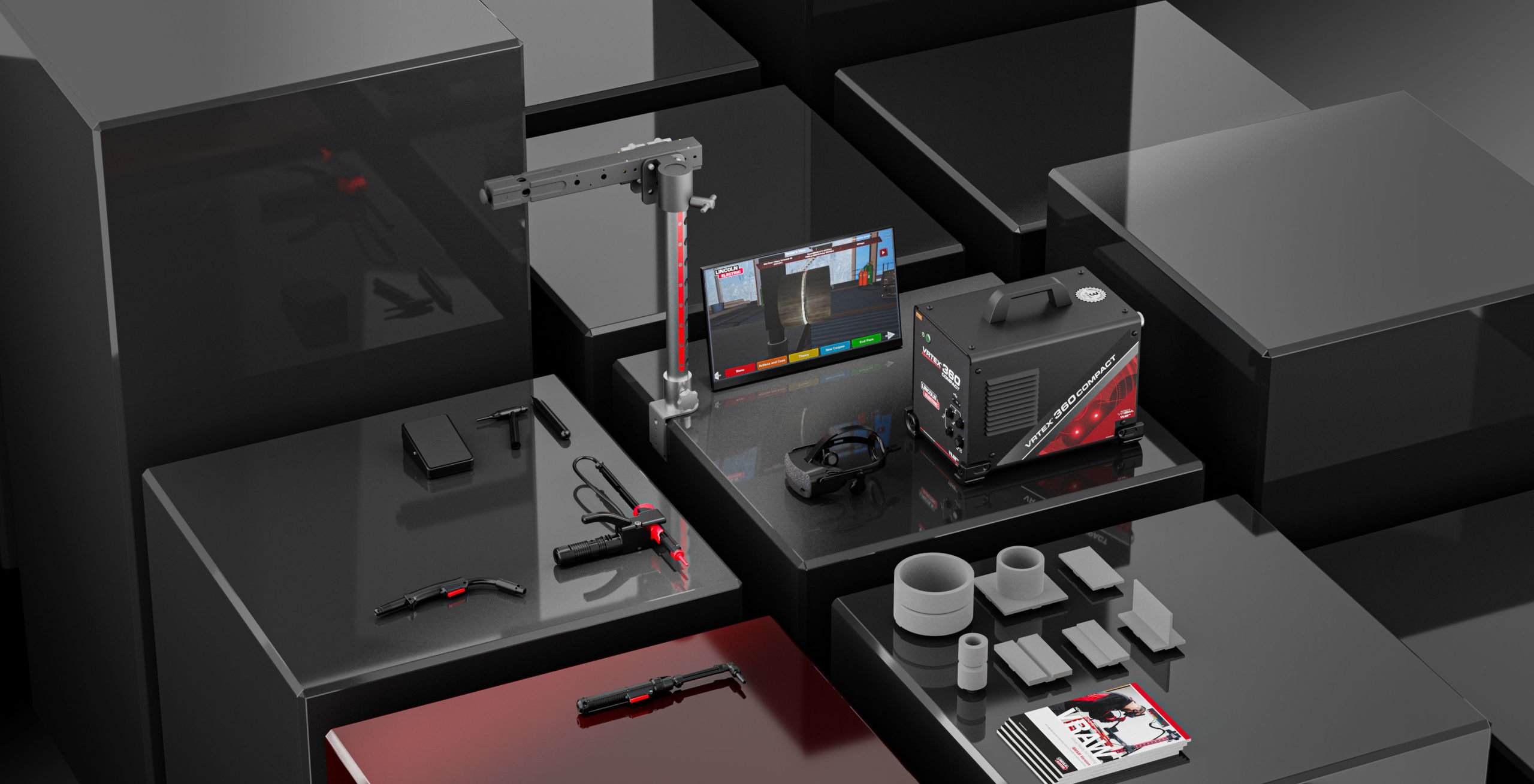

Discover our immersive welding training solutions.